Low Profile – High Performance

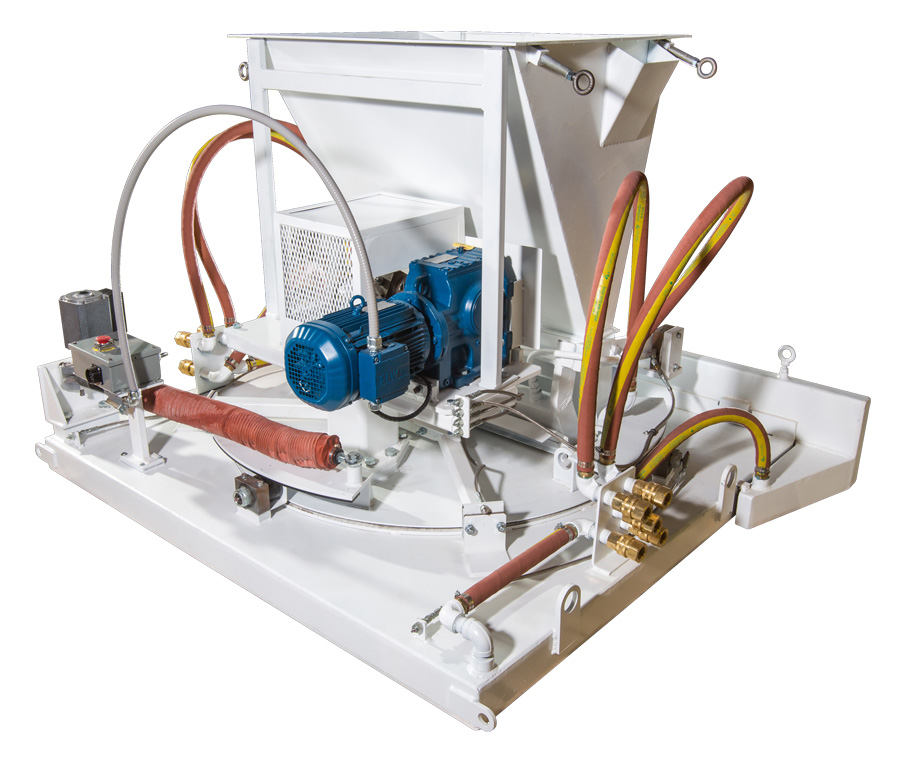

Designed and built to be the most rugged and long lasting charger available on the market today, Global Glass’ Oscillating Batch Charger incorporates the turntable within the fixed base of the charger to provide utmost flexibility in directional batch charging.

The Ganaglass Oscillating Batch Charger integrates key features of the company’s stationary charger to promote improved sealing of the doghouse, reduced wear and ease of service.

A bi-directional linear actuator positions the turntable to provide up to 44° of charging oscillation. Five End Stop and Positioning switches are included within the switch housing of the actuator motor. Each switch is adjustable to allow for asymmetric oscillation and patterned charging.

Flexibility increases since the charging and oscillating motor drives are completely independent. Virtually any batch charging pattern can be achieved when used with the optional Charger Positioning Control System.

Optional cooling water temperature and pressure sensors provide constant monitoring of cooling water with alarms if temperature or pressure limits are exceeded. The monitoring of the cooling water helps prevent water box damage due to over-temperature, over-pressure, or loss of cooling water.

Abrasion resistant coatings are available for mild steel units on high wear areas for use in installations with high cullet percentages or oversized cullet.

Global Glass also offers a charger cooling skid for installations with unsuitable cooling water supplies. A single cooling skid can be configured to supply adequate water for multiple chargers. The skid utilizes a closed loop system and can be filled with straight water or a 50/50 water glycol mix.

Features:

- ½” stainless steel bottom plates

- 3 HP gear motor

- Single level design

- 44° of oscillation

- Five adjustable positioning sensors

- Centralized lubrication system

- Three (3) independent water boxes

- Internal water channels for greater cooling efficiency

- Heat shields to protect bearings

- Sealed design to reduce NOx intrusion

- Compressed air coupling for emergency cooling

- Variable speed AC or DC motor drives

- Automatic process controls

- Quick disconnects for ease of maintenance

- Fabrication in mild, stainless steel or other alloys

- 2-year warranty on material and workmanship

- Lifetime support

Benefits:

- Lowered energy consumption

- Improved melting capability

- Reduced construction cost

- Precise feed rate control

- Least regard to consistency of batch

- Provides charge velocity into the melter

- Transfer kinetic energy to glass

- Maximize exposure to melting energy

- Minimize heat loss around charger

- Simplified doghouse construction

- Low Total Cost of Ownership

Installation Options:

- Custom hoppers and transition chutes

- Cooling skid for high particulate water installations

- Variety of sizes to suit charging capacities up to 525 tons per day

Controls:

- Pusher positioning and discrete charging

- Batch Master 3 control panels for multi-charger installations